DAY 3- 9

JULY 2012

Assalamualaikum

and Salam Sejahtera..

My task

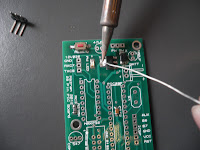

for today is continue with soldering process. The first thing I need to do is

to soldered an SMD component first. Before starts to soldering process, we must

know the procedure of surface mount components. A good eye, a steady hand and a

soldering iron with a small, clean tip are required. We are using pin by pin

method. This method are used for two pin components such as capacitor and

resistor,small outline package and SOT

SMD

Components Soldering procedure

1)Place

a small amount of solder on one of the two pads. Approximately 0.5mm in height.

2) Grab the part with very fine tweezers. Bring the part overtop of the pads, slight to one side so that the part can sit flat against the PCB. Heat the pad already with solder and slide the part onto the pad so that it is centered between the pads. Remove heat.

3) Put a small force down on the

part and re-heat the one pad to guarantee that the parts is flat against the

PCB

4) \Solder the other side of the part

5) The solderings should not look like "round ball" on either side of the parts. If this is the cast, there is too much solder being appied to the joint. A properly soldered joint should have a curved line from the end of the pad to the top of the part.

|

SMD components that has been soldered

Through

Hole Component Soldering Procedure

1)After we prepare all components that

we need to use for solder, we need to clean component lead and make sure it’s

clean from dirt & smear.

2)Then we can insert the component and

clinch lead. We need to cut off the excess wire first before we continued with

soldering process

3) Next, we need to apply flux to

soldering point. The purpose of applying flux to soldering point is to remove

oxide layer from the base metal surface, to shield base metal surface from

oxygen which re-oxidizemetal and to lower solder’s surface tension to improve

wetting

4)Before soldering, we need to make

sure that we are using only well-heated soldering iron. Clean soldering iron

tip and then apply a bit of solder to iron tip. We need to ensure that solder

are attached to tip.

5)In order to solder the point, we

need to heat the soldering point first and soldering iron must contact both

component lead and pcb copper.

6)Then apply solder wire and ensure

that solder wire must contact both component lead and pcb copper.

7)Pull away soldering wire from solder

point. Then pull away soldering iron from solder point when solder becomes

shiny.

8) During soldering process, the timing

is important. Do not apply soldering iron too long or too short.

Complete

ACCEPTANCE CRITERIA OF SOLDERING

There is a criteria of good soldering that have been set

up base on IPC-A-610 and J-STD-001 (Class 2)

Criteria:

• Circumferential

fillet and wetting= 270°

• Percentage of

PCB copper landarea covered with solder = 75%

• Visible good

wetting

• Fillet Height

= minimum ¼ Leadheight or 0.05mm

• Lead height

after cut =maximum 2.5mm

• Solder finish

= glossy or shinny

• Solder contact angle ≤90°

|

1

No comments:

Post a Comment